6 mai 2024

The Hub of a Supply Chain:

When we tell our loved ones that we work in supply chain management, they often don't quite understand what we do. The common response is, "Oh, so you're in logistics." And the answer is yes, but it's not the whole picture.

This supply chain can be divided into three flows:

Physical flow, which is the most obvious.

Information flow.

Financial flow.

1- Physical Flow:

This involves the movement and storage of goods. It starts from a production site, then possibly goes to one or more warehouses, and eventually reaches a store or final customer. This is what most people think about – the storage and transportation of goods, often associated with logistics.

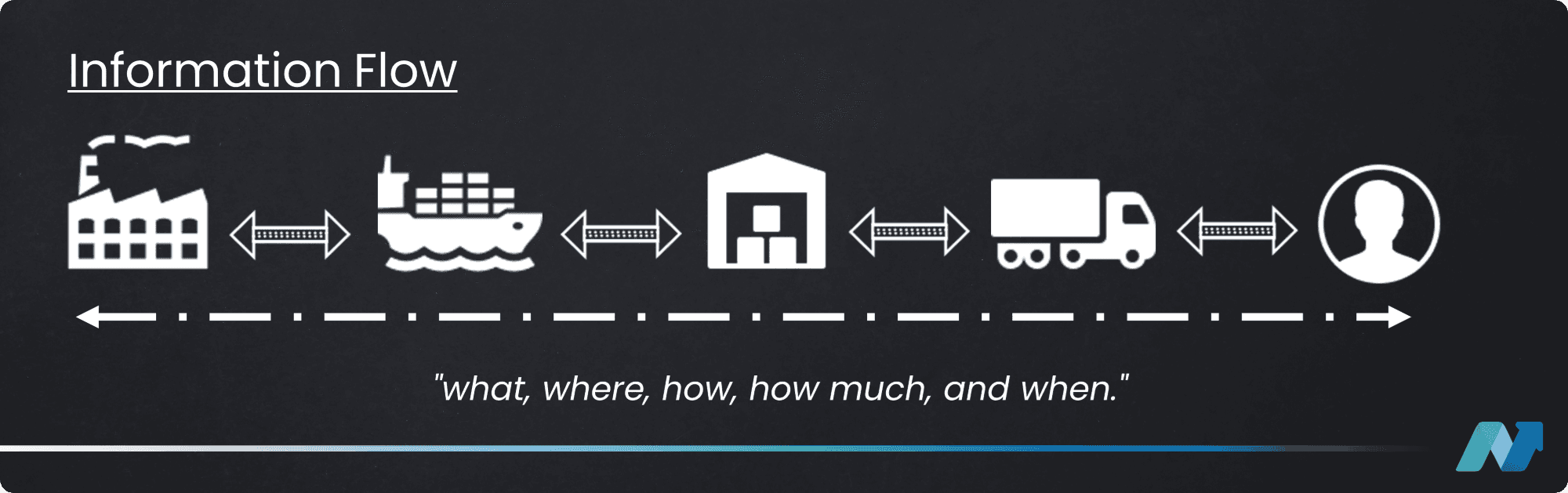

2- Information Flow:

This can be seen as the brain that controls the physical flow. It contains a wealth of information, summarized by "what, where, how, how much, and when." It includes all information about products, suppliers, and supply chain strategies.

For example, you might need to decide whether it's better to source from Asia for lower costs but longer lead times, or from a closer location at a higher purchase price. It also involves information about your service providers, logistics partners, customs, pricing, sales history, movements, and performance indicators.

Managing this information is crucial for predicting the future. If you can foresee what's coming, supply chain management becomes optimal and straightforward.

3- Financial Flow:

While this can be considered part of the information flow, managing finances is a strategy in itself. In large companies, this involves dealing with different currencies and managing money flow between suppliers and within the company.

So, we have these three flows – physical, information, and financial. The challenge of this supply chain is to manage these flows.

In terms of organization, supply chain directors generally put the following people in charge:

A logistics manager who handles the physical flow.

A demand planner for forecasting and planning.

A person responsible for IT and financial aspects, often alongside a finance department.

We can summarize the challenges of the supply chain with this very simple sentence:

" make these products accessible at the right time, in the right place, and at the best price."

The Future of Supply Chain?

Google Trends is a tool that visualizes search volumes on Google over time. The graph is based on keywords such as big data, machine learning, data science, and deep learning, all related to data management.

In recent years, there has been a significant increase in searches related to data management. The common challenges include data storage, data collection, data centralization, data analysis, and talent management.

These data are fundamental for optimizing forecasts and the profitability of your supply chain. Today, over 85% of companies still use Excel for very basic management. There's a growing gap between these companies and those adopting a more intelligent, data-driven approach.

Organizations that invest in supply chain visibility can reduce supply chain costs by 5-15% (Source: Deloitte). By 2025, the global big data market in the supply chain is forecasted to reach $4.4 billion, up from $0.9 billion in 2016 (Source: Statista).

The challenge in the coming years is to transition from traditional to intelligent supply chain management based on data. If you ever need to switch careers or invest your time wisely, this is the field that's making a difference.

Technologies for leveraging data and achieving proactive management of your supply chain :

This is where software like "Fluid" comes in, an innovative SaaS solution for supply chain management challenges.

It helps businesses better understand market risks and trends, facilitates communication and collaboration among supply chain actors, and ensures quality and safety throughout the process.

For example, Fluid offers a comprehensive suite of tools and features designed to optimize every aspect of the supply chain. From inventory management to order fulfillment, it provides real-time insights and analytics that empower businesses to make informed decisions and drive operational efficiency.

Conclusion :

Here are the key areas to focus on for flawless supply chain management and maximum efficiency

Be agile and adaptable to market changes by implementing flexible and responsive processes.

Use technologies and predictive analytics tools to anticipate future needs and optimize your stocks and resources.

Establish strong partnerships with your suppliers and service providers to ensure the quality and reliability of products and services.

Stay customer-focused by continually seeking to improve the customer experience at every stage of the supply chain.

By following these guidelines, you can build a resilient and efficient supply chain that is well-equipped to navigate the complexities of today's business landscape.

Driving Customer intimacy in global Supply Chains with Fluid

25 mars 2024

Customer intimacy is about developing close bonds with customers by understanding their needs and delivering tailored experiences. Fluid, a cutting-edge SaaS and CRM platform, addresses the challenges of achieving customer intimacy in global supply chains. It offers a unified portal for client interactions, streamlines data reporting, incorporates built-in CRM functionality, uses advanced segmentation for personalization, and introduces gamification and rewards to foster lasting loyalty. Fluid empowers businesses to build deep and lasting connections with customers, meeting the demands of a dynamic and interconnected business environment.

A Supply Chain Story

27 févr. 2024

Fluid is an innovative SaaS solution that helps businesses tackle the challenges of an increasingly complex supply chain. By providing transparency, traceability, product quality, and data security, Fluid enables companies to better understand market risks and trends, facilitates communication and collaboration among supply chain actors, and ensures quality and security throughout the process. This transforms the supply chain into a competitive advantage.